Aeration Methods In Water Treatment

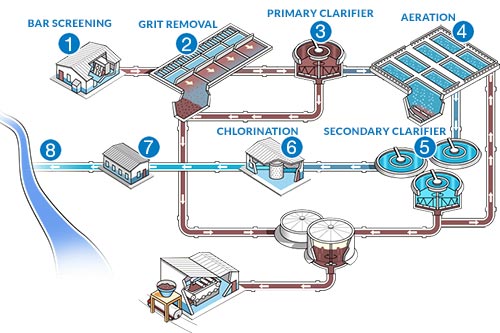

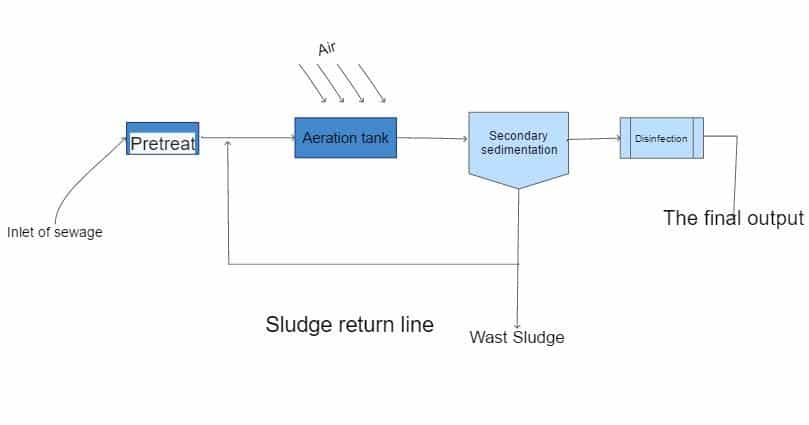

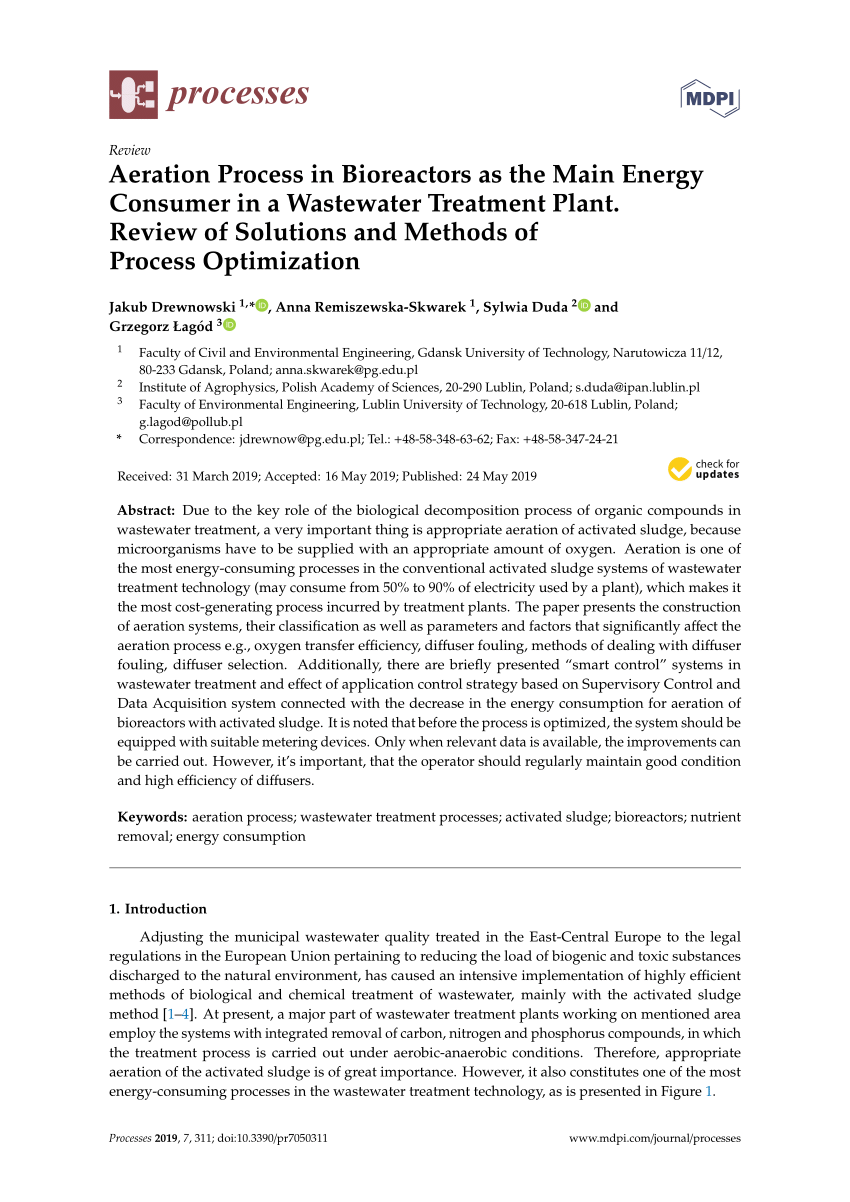

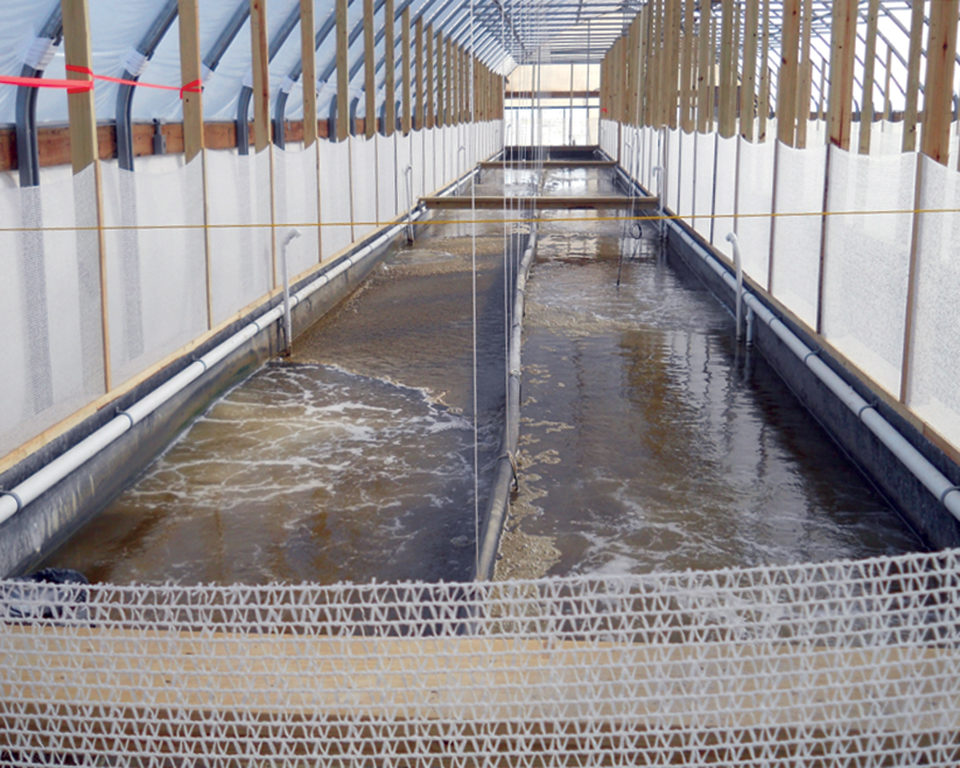

In municipal and industrial wastewater treatment aeration is part of the stage known as the secondary treatment process.

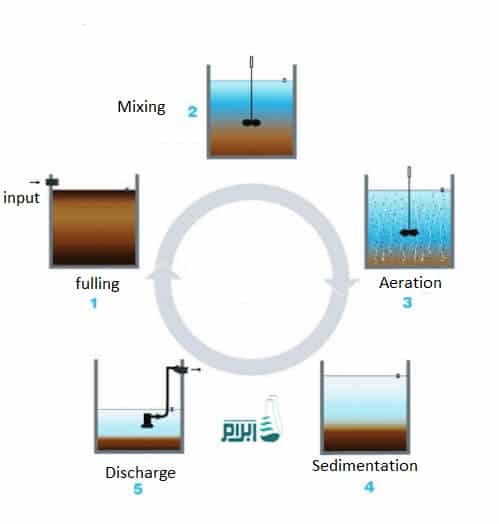

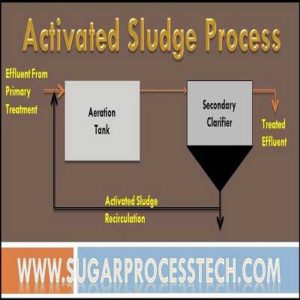

Aeration methods in water treatment. The aerator activates the sludge process by pumping air into a tank which results in increased microbial growth in the wastewater. Microorganisms in aeration wastewater treatment tanks break down organic compounds and nutrients. The ultimate objective of the air injection system is to get as much dissolved oxygen into as much contact with the biomass and dissolved organic material as. These microbes start eating the organic material and form the flocks that get settled easily.

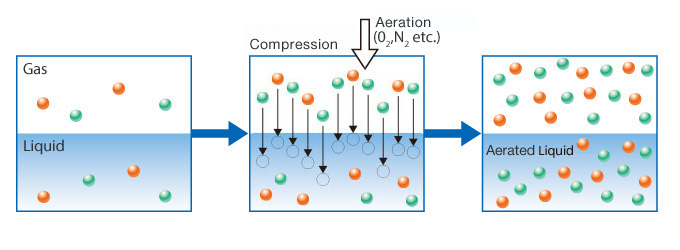

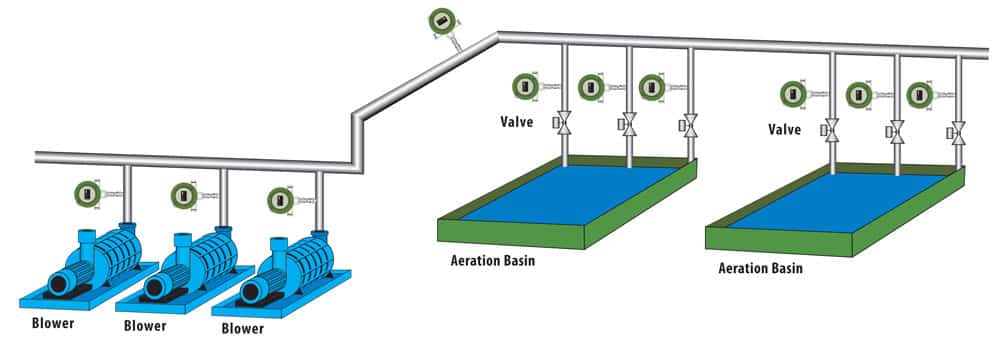

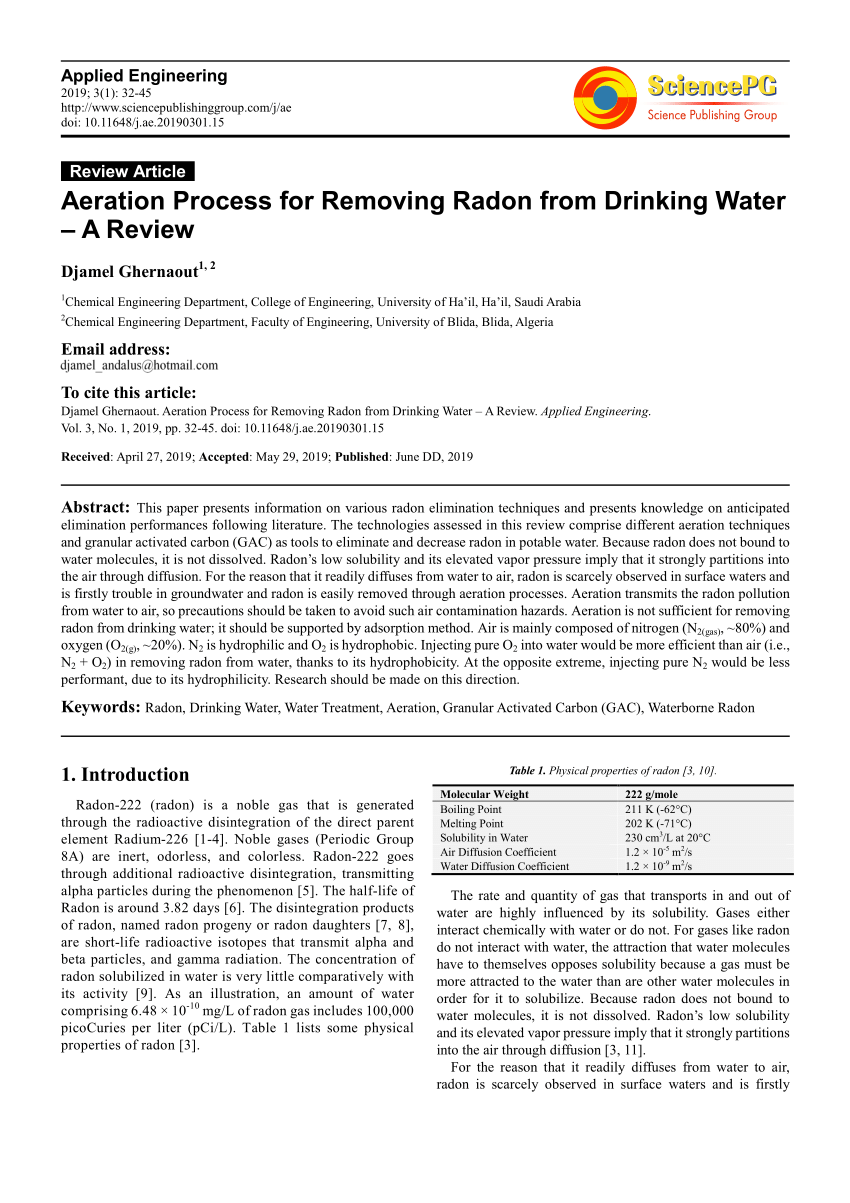

Two general methods may be used for the aeration of water. If the gas accumulates directly above the water the process. There are numerous practical methods that have been developed to inject air into a body of water. However the designer of the system needs to consider how the gas is discharged from the aerator.

Aeration is also an effective method of bacteria control. The turbulence from the aerator will easily displace the gas from the water. Aeration is the most common choice for removal of hydrogen sulfide from water. The most common in industrial use is the water fall aerator.

After they get settled in a separate settling tank these bacteria flocks are then. The air causes the dissolved gases or volatile compounds to release from the water. The air and the contaminants released from the water are vented. When to use aeration.

Many industrial and municipal wastewater treatment plants use the aeration process. Aeration treatment consists of passing large amounts of air through water and then venting the air outside. The activated sludge process is the most common option in secondary treatment. Aeration in an activated sludge process is based on pumping air into a tank which promotes the microbial growth in the wastewater.

Aerator in water treatment plant works in the secondary treatment process. Aeration is an important step in the process of treating wastewater including sewage effluent. In waste water treatment the holding tank into which air is injected and which contains waste water and biomass is known as a bioreactor. The water can then move through a filter to trap the iron and manganese particles.

Through the use of spray nozzles the water is broken up into small droplets or a thin film to enhance countercurrent air contact. In the case of iron and manganese the air causes these minerals to move from their dissolved state to a solid state and precipitate out of solution. Through the use of spray nozzles the water is broken up into small droplets or a thin film to enhance countercurrent air contact. The most common in industrial use is the water fall aerator.